Materials: Steel, Wood, Synthetics

I strive to use the best materials possible in every step of my process when making knives. The materials I use are always subject to change as I discover new sources, new products, and new methods to improve my process.

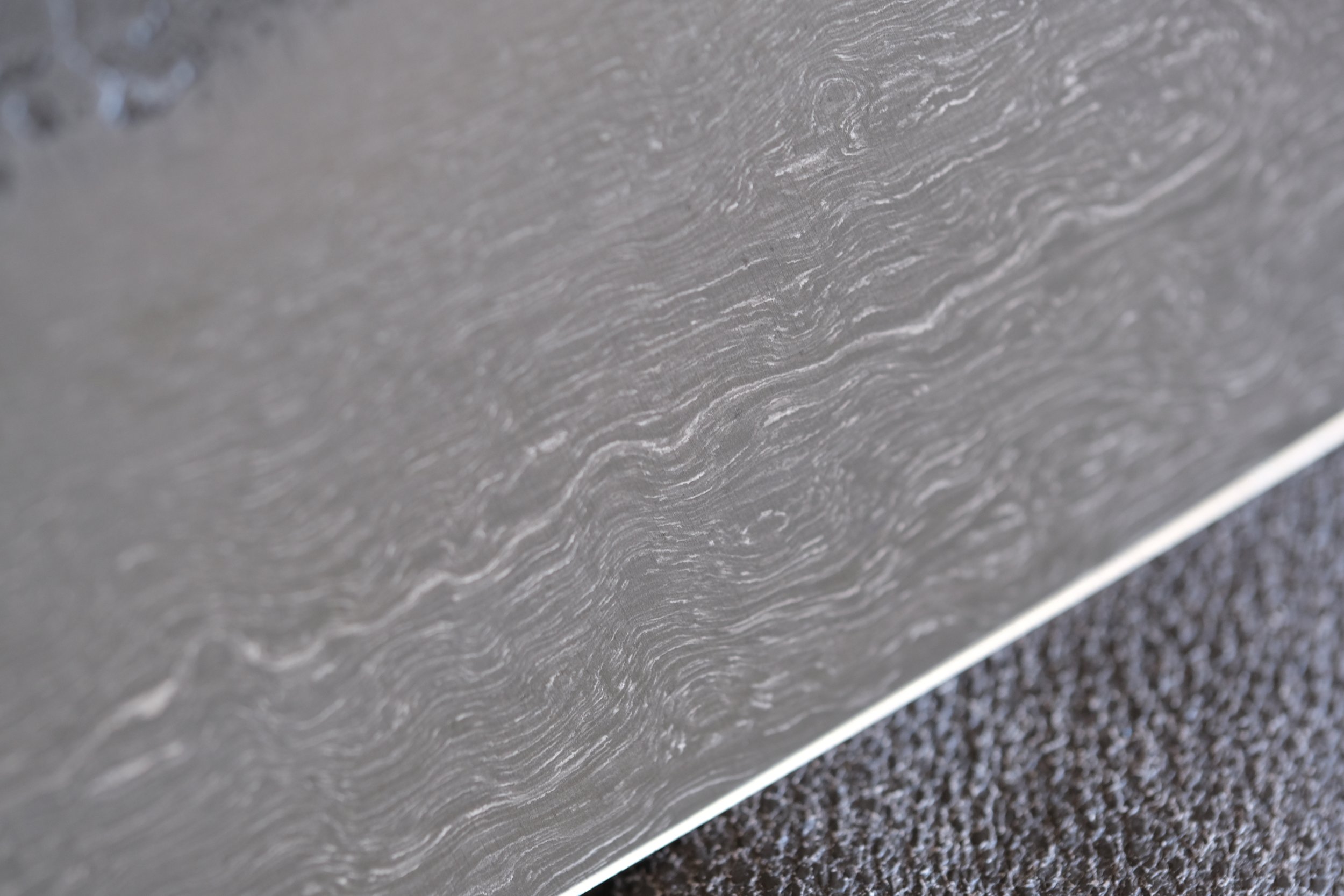

Steels

I use premium Carbon Steels from all over the world. I am constantly experimenting with new steels and heat treatments while seeking to find the balance between hardness, toughness, and sharpenability. Here are some of the steels I have used or am using.

These are all non-stainless steels. For information on care, take a look at the Knife Care page.

1084

Carbon: .84%

Manganese: .75%

Phosphorous: .04%

Silicon: .22%

Sulpher: .05%

Often referred to as a “beginner’s steel” 1084 is extremely forgiving. It is relatively easy to forge and to heat treat. Simple as it is, it still makes very good knives. If treated properly it can get up to 62 Hrc and still be usable as a kitchen knife, but it tends to thrive in the range of 58-61 Hrc. Because of the wide variety of sizes/dimensions available, it is often my choice for large knives such as cleavers. It is also the most common steel paired with 15N20 in Damascus Steel

26c3/Sheffcut

Carbon: 1.25%

Chromium: .30%

Manganese: .40%

Phosphorus: .02%

Sulphur: .01%

Silicon: .20%

26c3, produced in Sheffield, England, was originally intended for the production of razor blades. Also referred to as “Spicy White” for its chemical similarity to Hitachi’s Shirogami 1 (White Paper steel). Its extremely pure and excels at taking very fine, thin edges. It does not have especially high toughness or abrasion resistance which means it really isn’t suited for hard use knives, but I don’t categorize kitchen knives as “hard use” since they are generally used to cut soft things: food. 26c3 takes an extremely sharp edge is a joy to resharpen. It is fast becoming one of my favorite steels - expect to see it more of it in my knives soon. Sheffcut is essentially the same steel with the addition of Niobium and a tiny bit more carbon, which increases the abrasion resistance. My target hardness for these steels is 64 Hrc.

1.2419 Tungsten Steel

Carbon: 1.05%

Silicon: .24%

Manganese: .84%

Tungsten: 1.06%

Chromium: .92%

Phosphorus: .02%

The addition of tungsten to low-alloy carbon steels increases their abrasion resistance and hardness due to the presence of extra hard tungsten carbides. This steel hits the sweet spot of hardness and edge retention in my opinion. Holds an edge very well but still sharpens easily. The added tungsten makes this steel a little harder to forge and grind but the results are well worth it. Highly recommended for professional chefs. Target hardness for me is 63 Hrc.

52100

Carbon: 1.00%

Chromium: 1.50%

Manganese: .30%

Silicon: .25%

One of my go-to steels, 52100 offers a good balance of hardness and toughness. Traditionally used in high-pressure application like ball bearings, it has become a cornerstone steel for the Western knife making world. Although a deep hardening steel (doesn’t require a super fast quench), it requires accurate temperature control to get the best performance. My heat-treatment procedure usually yields hardness between 61 - 63 Hrc. One of my favorite steels to use as the core in laminated billets.

W2

Carbon: ~.95%

Chromium: .10"%

Silicon: .19%

Manganese: .20%

Phosophorus: .01%

Vanadium: .17%

Tungsten: .02%

W2 is another iconic steel for American knifemakers. It is renowned for its ability to take a striking hamon. Prior to the quench, clay or refractory cement is applied to the spine of the knife. The parts that are covered in clay stay insulated and cool at a slower rate than the exposed parts of the steel, resulting in hardened and un-hardened parts of the blade (also called a differential heat treat). Via polishing and etching the hardening line is exposed. It can be very beautiful aesthetically, and functionally the softened spine makes the blade tougher and more resistant to breaking if dropped. W2 gets very hard (62-64 Hrc) but it is not the toughest steel. Therefore my favorite application is slicing knives that take advantage of its ability to hold a very fine, hard edge but aren’t heavily abused. Comparable to Hitachi’s White #2 Steel.

Apex Ultra

Carbon: 1.25%

Tungsten: 2.60%

Vanadium: .40%

Chromium: 1.5%

Manganese: .30%

Silicon: .35%

Apex Ultra is considered the finest Low Alloy culinary steel currently available. It was designed by a trio of Knifemakers and Metallurgists. It has a high carbon content, significant tungsten, vanadium. and chromium, all of which produce a high quantity of very hard carbides. The result, post heat treatment, is extremely high hardness and abrasion resistance - the best available for non stainless steels. This steel will take a very fine edge and keep it for a long time. The biggest drawbacks to Apex Ultra are its availability (currently very small quantities are produced), its relatively high level of difficulty to forge, heat treat, and grind, and its cost. Also, its extreme abrasion resistance makes it somewhat difficult to sharpen.

Handle Materials

Natural Wood

I use a variety of woods that don’t require stabilization due to their density and hardeness. They are often very oily, heavy, and difficult to work. They generally require minimal finishing due to their stability and water-resistance.

Examples of natural woods that I use:

Dessert Ironwood

African Blackwood

Walnut (sometimes stabilized)

Padauk

Purpleheart

Cocobolo

Zebrawood

Oak (sometimes stabilized)

Stabilized Wood

Some species of wood require stabilization to make effective knife handles. They’re either too soft, too light, or too prone to cracking and warping. Often the most beautiful wood grain comes from something invasive, such as fungal spalting or the remnants of insect life (like Ambrosia beetles in maple trees). Other times a tree might produce a big, lumpy growth called a burl, where the grain grows in lots of different directions. In order to be useful, these woods need to be stabilized. Not only wood can be stabilized - other material such as antler, bone, and stone are often stabilized.

The stabilization process goes something like this: The material to be stabilized is submerged in resin while under vacuum (at this point dye can be added if desired). The vacuum pulls the air from the pores of the wood and resin gradually replaces it. The wood is usually left for many hours under vacuum. After a sufficient soak time, the vacuum is turned off and the wood is left to soak awhile longer. Then, the wood is removed and cured in a low temperature oven for a couple hours. The resulting product is often triple the weight of the original, water resistant, hard, and far less likely to change shape or size over time. Hence, stable.

Synthetics & Metals

Micarta, G10, and Polyresin

Synthetic materials offer many advantages. They tend to be very consistent in quality and they are very stable, durable, and resistant to water damage. They can also be very attractive.

Micarta: Layers of fiber compressed and cured with resin. The fibers act as reinforcement to the cured resin. The fibers used most commonly are canvas, paper, and linen.

G10/Garolite: Same concept as Micarta. Layers of fiberglass cloth are soaked in epoxy resin and compressed until cured. Usually G10 is produced in thinner sheets than micarta.

Polyresin: Essentially a plastic, polyresin is relatively lightweight and durable. It has good resistance to water damage. It is often combined with mineral dusts and dyes during production to create swirling patterns.

Metals

I use a variety of metals, both ferrous and non-ferrous, for bolsters, spacers, or pins. The ones I use most commonly are copper, brass, mild steel, and stainless steel. Copper especially will oxidize with time in a similar to carbon steel. Sometimes I will force a patina on copper alloy spacers and bolsters to pre-age them.